![[file_field:filename]](https://www.osmos-group.com/sites/default/files/styles/project_770x270/public/Actus/pontbanargecom_0.png?itok=L4LwVABF)

The Banarge Bridge, located in the Lot-et-Garonne department in the commune of Saint Pierre-sur-Dropt, is a road structure with prestressed girders that provides a link between the two banks of the Dropt. The bridge is limited in tonnage (40 tons). The project owner wishes to lift the tonnage limitation which prohibits the passage of certain common loads of the road code (44 tons). The project owner was also questioned because of the circulation of convoys of unauthorized gauges.

An investigation campaign (SETRA protocol) was launched on this bridge with post-tensioned beams built in 1955. The integrity of the structure was verified and the recalculation was carried out. In addition, the project owner wanted to understand the number of oversized convoys and the dynamic consequences of this traffic on the behaviour of the structure. The owner sought several information: the frequency of passage of the heavy convoys, the nature of the convoy, the weight, the distribution of the loads.

In order to provide the Lot-et-Garonne department with answers as to the real level of service of the road structure and its impact on the health of the structure, OSMOS implemented its solution of dynamic weighing in motion by instrumented bridge: Weigh-in-Motion + Deformation (WiM+D®).

OSMOS reinvents dynamic weighing and offers a unique solution for measuring the weight of heavy vehicles and exceptional transports.

Traditional weigh-in-motion solutions require roadway work, and continuous monitoring of structures is usually done by visual inspections or with other measuring devices on the bridge. Under these conditions, it is very difficult to measure the weight and dimensions of vehicles and simultaneously assess the effects of their passage on the mechanical behavior of bridges, although this is one of the main factors in their accelerated degradation.

OSMOS has therefore developed a reliable and automatic weigh-in-motion technique based on the dynamic analysis of the structural deformations of the bridge deck. By simply placing a few Optical Strands under the bridge deck (beams and/or slabs), in a non-intrusive way for the roadway and the structure, the system automatically counts and weighs the heavy vehicles. From this information, the OSMOS teams quantify precisely the impact of these heavy vehicle passages on the mechanical functioning of the structure.

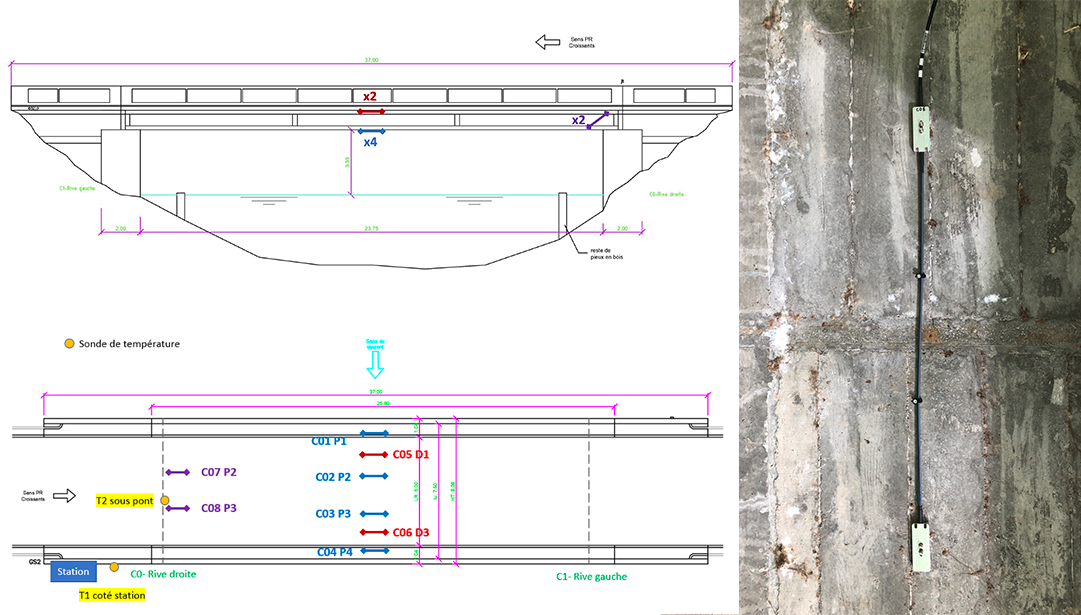

Configuration of the OSMOS WiM+D® solution for the Banarge Bridge

For this structure, 6 Optical Strands were installed at mid-span on the underside of the deck: 4 under the main girders at mid-span and 2 under the slab, for axle detection, one per traffic lane. The installation and removal of the measuring device on the structure was done in one day using an aerial work platform.

Bridge Instrumentation: Transverse and top views of the bridge with sensor locations; Optical Strand installed under the deck

The OSMOS WiM+D® measurement system was calibrated just after its implementation by performing a dynamic load test without traffic interruption. This step allowed to identify the dynamic signatures associated with the different test loads and to verify the behavior of the deck under the effect of these passages.

Following the load test, the device was remotely parameterized and continuous monitoring of the structure was carried out for one year in order to measure the road traffic over a reference period representative of the real level of service. The information obtained was also used to analyze and monitor the evolution of its mechanical behavior regarding traffic-induced stresses.

The structural monitoring system was also coupled with a video surveillance system. The wide-field camera installed on site allowed the identification and filming of the passages of each truck and exceptional transport. This optional device is synchronized with the monitoring device and can be configured to record convoys exceeding a load limit. It thus reinforces the controls in case of overloads.

A video example of a truck passage in relation with the data recorded in real time on the structure is available on the OSMOS YouTube channel:

What information is available and what are the conclusions of the study conducted on the Banarge Bridge?

Each user can access the vehicle passage history via a dashboard with the Safe WiM+D® application, and benefits from an accurate and statistical view of the road traffic. This application is simply accessible via a web page where each record is available on average one minute after the passage of the convoy.

The application can be configured according to the information required by each user: selection of the analysis period, sorting of all the recordings, display by weight and direction of traffic, and publication in pdf format of the detailed sheets for each convoy.

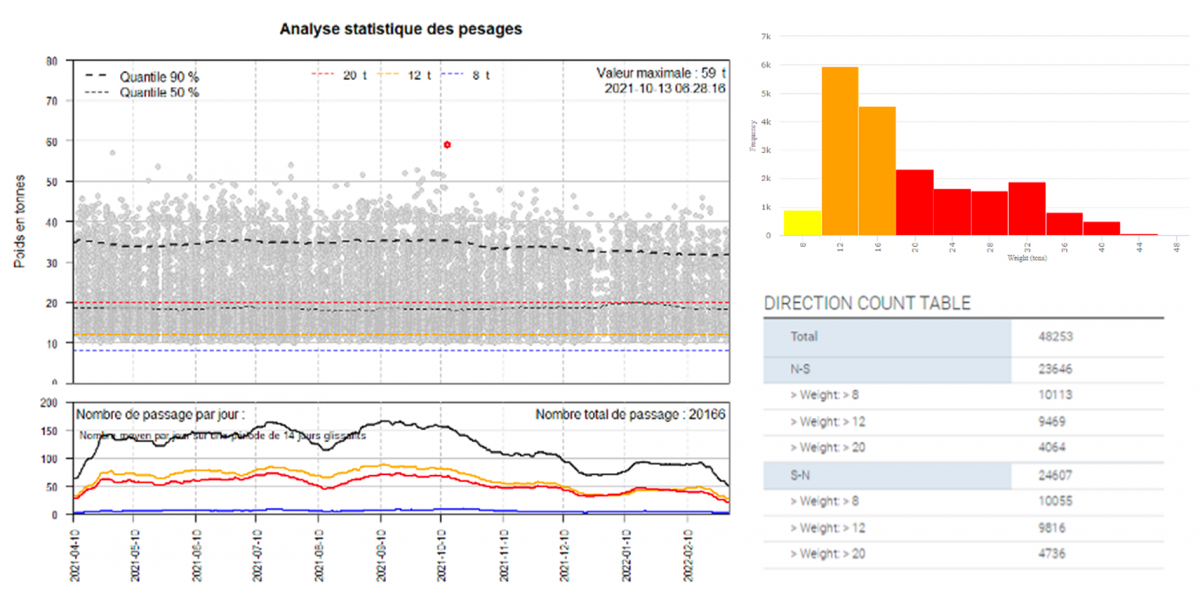

As an example, the graph below summarizes all the weighings carried out. Each point corresponds to the weight and the date of the vehicles' passages. The colored curves represent the number of passages by weight category and the histogram their distribution by weight range (in this case: vehicles of more than 8 tons, more than 12 tons and more than 20 tons).

From left to right: Statistical analysis of truck crossing - History of crossing broken down by weight category and by direction available via the WiM+D dashboard

Over the course of one year of monitoring, starting in March 2021, nearly 20,200 weighings were recorded on the Banarge Bridge, based on the dynamic data automatically recorded by the OSMOS WiM+D® system.

The analysis of the structural deformations recorded since the beginning of the monitoring also showed that the effects of traffic loads on the bridge were statistically stable, with no sign of weakening of the structure.

The OSMOS WiM+D® solution has allowed the project owner to confirm the hypotheses concerning the response of the Banarge Bridge structure and to ensure its good mechanical behavior, but also to obtain precise and statistical information on the actual level of service of the structure.

By opting for this solution, the Lot-et-Garonne Department is able to confirm the safety of users and the durability of the structure. The Department has chosen to schedule reinforcement work on the bridge to remove the 40-ton tonnage limit.

Testimony of Jean-Luc PROST, Head of the Engineering Works Department, Lot-et-Garonne Departmental Council:

Why did you choose OSMOS' services?

The technical proposal is innovative and allows a non-destructive implementation. The weighing completes the traditional road counting system.

The coupling of the video and the weighing allows to compare the results of the measurement and the modeling of the convoy with its reality. All the readings are relevant to help the project owner.

What do you think of the OSMOS WiM+D tool (weighing in motion and analysis of structural deformations)? What are its advantages for bridge management?

The device makes it possible to identify the heavy loads that actually cross the structure. Weighing and imaging are complementary. They have allowed us to measure the weight of convoys, to understand the passage of very heavy axles and to adjust the weighing models.

How did you integrate the analysis results into your project management?

The analysis provided visibility on the 40-ton gauge overruns, but also, dynamic information that complements the structural integrity analysis.

Did OSMOS meet your expectations? What benefits did you get from the monitoring?

The coupling of the weighing with the video of the convoy contributed to the understanding of the stresses of the structure by the client. And the data concerning the deformation were useful to confirm the calculation model of the structure. The data collection was fast. The modeling of the weighing required several calibrations. The exchanges with the support services allowed to answer the expectations of the project owner.