Extending over a length of 7.2 miles (11.6 km), the Mont Blanc Tunnel is a strategic feat of engineering that offers fast travel between France and Italy. It is a major trade route that supports the local and inter-regional economy. In fact, substantial traffic travels along it daily, contributing to its wear and tear. The tunnel is operated by a Franco-Italian organization, the GEIE-TMB (Mont Blanc Tunnel European Economic Interest Group). The company is responsible for the tunnel’s structural monitoring and maintenance, as well as traffic safety and management.

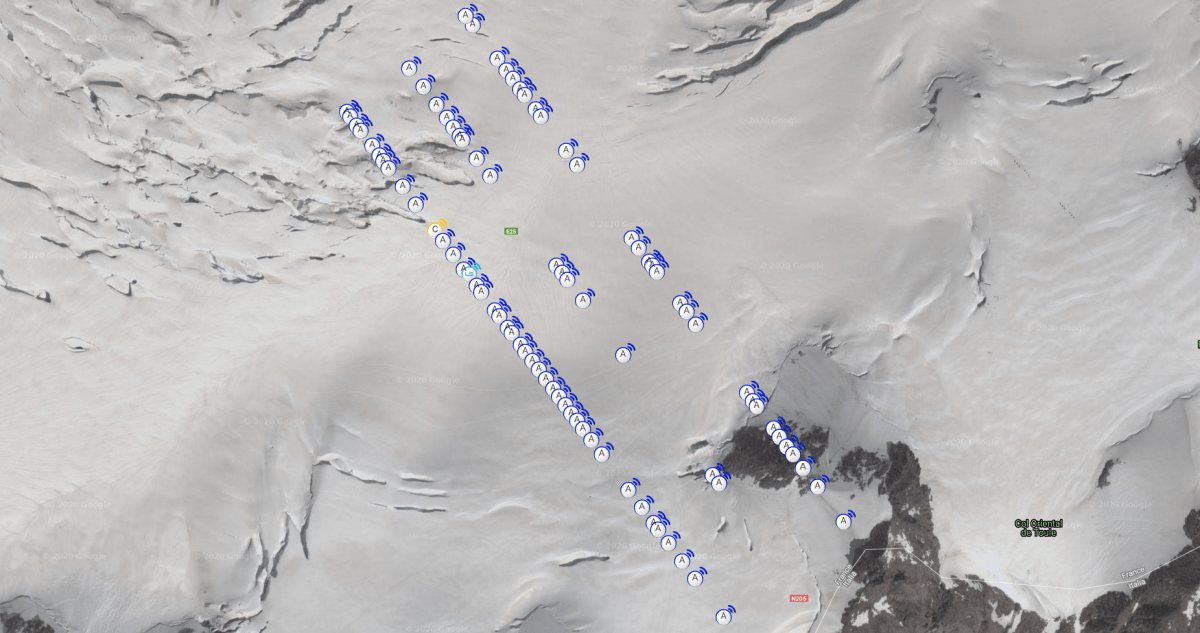

Today, the Mont Blanc Tunnel is a model in terms of safety, particularly with regard to structural aspects. 117 LIRIS Optical Strands installed under the surface of the road provide for its continuous monitoring. The tunnel’s instrumentation is designed to track and analyze its mechanical behavior, particularly as a result of road traffic, and its evolution over time.

Static and dynamic measurements for a dual analysis of tunnel slab behavior

An average of 1,721 heavy vehicles pass through the tunnel, each and every day. Those crossings are dynamic stresses, of varying intensity, that contribute to the structure’s aging. The OSMOS monitoring system measures the effects of those events, which represent not only loads that cause stress to the structure, but also the associated strains on the material. Consequently, the slabs supporting the tunnel’s traffic lanes were equipped with LIRIS Optical Strands.

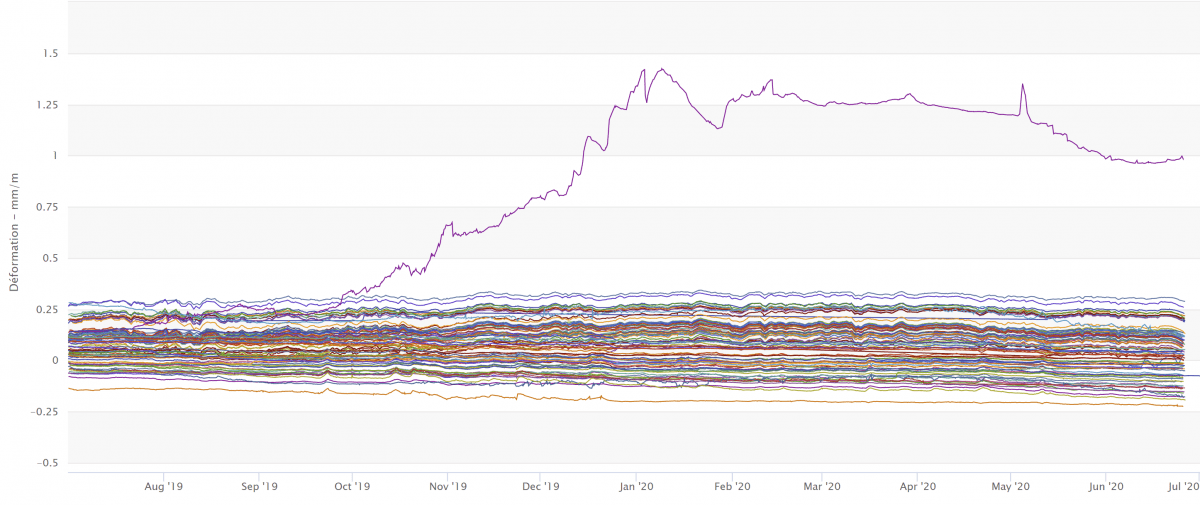

Over and above dynamic measurements, static analyses are an important part of this monitoring project. They involve measurements taken once an hour, to reveal slow-moving changes to the structure. Because the temperature is taken at the same time, these data can be used to study the structure’s response to fluctuations in heat. Then, OSMOS corrects for the effects of temperature, in order to identify any gradual trends caused by the aging of the structure.

As a result, the objective of the installed monitoring system, approved by the tunnel’s safety committee, consists of studying the mechanical behavior of the concerned slabs, by measuring deformation due to the bowing of the slabs’ undersides, owing to their own weight (static data) and/or to traffic loads (dynamic data).

The combination of these two types of analyses – static and dynamic – allows OSMOS to periodically calculate and assign a stability index to each sensor, as well as to the structure as a whole. The assigned score provides concrete, relevant information to the client, which can then review the structure’s state of health and any changes in its assessment over time.

Overview of the scores assigned to all of the sensors for the latest period (October 2019 to January 2020)

A preventative approach for optimized structural management

The Mont Blanc Tunnel monitoring project is, first and foremost, a preventive one. The goal is to anticipate any structural risks and adapt the level of service, if necessary. In some instances, notable changes to the structure’s behavior may lead to the implementation of protective measures or reinforcement work. By taking a proactive approach, the managers of the Mont Blanc Tunnel have secured the structure and were able to institute an optimized maintenance policy to keep it in a good state of health.

Overall, the structural behavior of the Mont Blanc Tunnel is very stable. Only one of the sensor locations has been characterized as “sensitive,” with significant changes in tension between October 2019 and January 2020. The reason for this abnormal measurement has been identified: a sliver of the reinforcing concrete cover had become detached in a ventilation shaft, causing the tensioning of the Optical Strand installed under the roadway. Since that problem was corrected, the structure’s behavior has stabilized completely and remains under continuous monitoring.

Graph of the deformation curves associated with all of the project’s sensors over the course of the past year (July 2019 to July 2020)